How to sharpen a meat grinder knife yourself?

A meat grinder is a very useful device in the kitchen sector, but over time, the quality and productivity of its work may deteriorate. This is manifested in the fact that when you rotate the handle you need to make more efforts, and the final product does not look ground, but transferred. Such a change in the operational properties of the meat grinder is due to the fact that its cutting surfaces are dull and developed. To solve the problem, some people turn to a specialist who has experience and the necessary equipment for sharpening for help, and, of course, pay for it. Others just buy a new meat grinder. But there is no need to take such drastic measures, since it is possible to restore the ability of this device to function normally at home without any help.

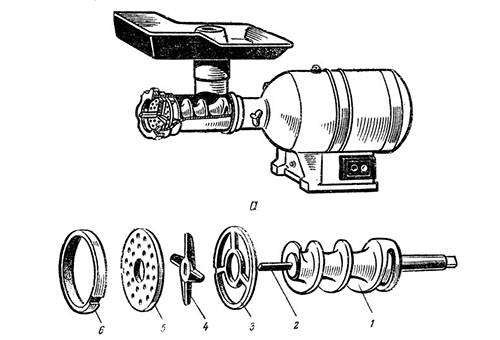

How does a meat grinder work and what parts may need sharpening?

First of all, you need to understand the principle of operation of this device. When you put a product in the receiving hole of a meat grinder for grinding and start to rotate its handle, the following processes occur inside the device.

- The spiral blades of the auger capture what you have laid and push the working mass towards the exit.

- Some parts of the product are pressed into the openings of a stationary knife - a round lattice plate fixed to the output of the meat grinder.

- Located at the end of the screw spiral, a movable four-blade knife cuts them off from the total mass;

- Each subsequent portion of the incoming material pushes the previous one out.

The cutting edges of the movable knife tend to become dull gradually, which naturally affects the efficiency of the meat grinder. But the quality of product processing also largely depends on the smooth interaction of a rotating and fixed knife. If there is too much distance between their cutting surfaces, then the movable knife will not cut, but tear and crush the working mass arriving for processing. This is due to the gradual production of metal.

If you look closely, you can see that the surface of both knives near the holes intended for their fastening on the axis is slightly higher than in places that are involved in the cutting process. But technology provides that these parts have one level over their entire surface. Due to this, the cutting edges of each of the four blades of a rotating knife will almost completely abut against the surface of the fixed grid plate. The situation can be corrected by machining the worked surfaces. This is a simple procedure, but it is important to perform it correctly.

Self-sharpening technology of a movable and stationary knife

If you decide at home to independently restore the functionality of the functional parts of the meat grinder to its normal state, then you will need a whetstone with small abrasive elements, the width of its working surface should be at least 80 mm, and the length should be at least 150 mm.

Tip

It is best to purchase a new stone, as the abrasive surface must be perfectly flat, that is, without working out, in order to achieve uniformity when processing metal.

It is also worthwhile to prepare a little water in advance so that it is at hand when you need to moisten the whetstone. In addition, it is desirable to fix the bar so that it does not break during operation.

First, you can machine the stationary knife, as it will take longer to grind. To do this, perform the following operations:

- moisten the abrasive surface with water;

- to press the grate to it with the inner side, with which the four-blade knife interacts with the mechanism;

- pressing on the center of the part, rubbing it on the surface of the bar in a circular motion, while turning all the time around its axis.

To control the process of sharpening a metal surface, you should periodically inspect it. If everything is done correctly, then in the first place those places where there is no production will be stacked. They will immediately be visible, since these parts of the surface will acquire a brilliant appearance. With further processing, these areas will gradually expand until the entire machined side of the part becomes shiny, which means that its surface has leveled off.

Tip

Do not forget to wet the whetstone so that the crumbled and crushed abrasive particles, mixed with water, form a layer of a kind of paste that will contribute to a smoother sharpening.

A rotating knife will be easier to sharpen, since its surface area is much smaller than a stationary one. The procedure for carrying out this procedure does not differ from that described in the above list. During the processing of the part, it is important to ensure that the surfaces of all four blades of the movable knife interacting with the grill do not have depressions and protrusions and are at the same level. It is important to carry out visual inspection all the time during processing so as not to remove the metal more than necessary. If even after sharpening, the cutting edges of the blades of the movable knife are not sharp enough, then you can carefully grind them from the back with a file or on an electric emery.